Thursday, October 23, 2025

Why Fieldworks AI Started with Door Design Mistakes

When we founded Fieldworks AI, we quickly realized that project engineers didn’t really need another tool to simply search drawings (…though yes, we built that too, like everyone else). What was missing was a way to help teams find the right information in construction documents.

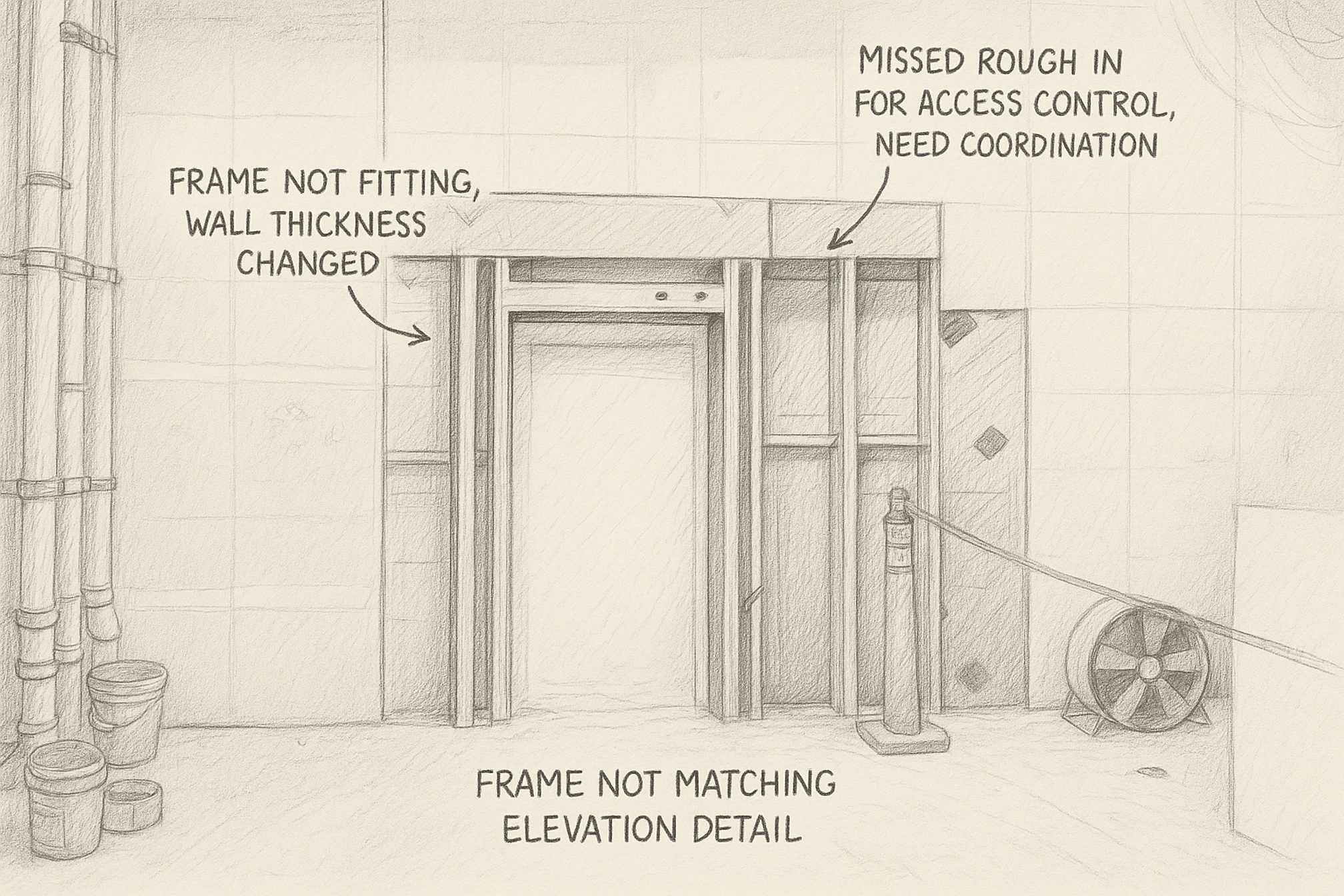

What do we mean by right information? More often than not, construction documents contain mistakes. The industry expectation is that general contractors and specialty trades catch those mistakes before the work begins. That puts enormous pressure on project engineers, project managers, and superintendents.

And finding design mistakes isn’t simple. It’s not just spotting missing references or a detail that never made it onto the sheet. Instead, it’s about performing real design checks and truly understanding the drawings (and the contract, and submittals, and… all of your construction documentation.) That’s a huge challenge.

So we asked ourselves: how can we prove this can be done in a specific, meaningful scope? We looked across every discipline… and we picked doors.

Here’s why.

1. Doors Can Delay Move-in

If you’re not in construction, it may sound surprising. But ask anyone with field experience: doors will absolutely hold up your certificate of occupancy. If a door swings the wrong way on an egress path, the panic hardware doesn’t match, or ADA clearances aren’t met, your client isn’t moving in.

The industry is full of stories where a “small” door issue snowballed into major delays. By catching these issues early, our AI helps avoid those last-minute headaches.

2. Doors Cut Across Multiple Trades

Doors aren’t just architectural details. They touch structural openings, security hardware, electrical access control, HVAC clearances, and life-safety codes. One door mistake can expose coordination gaps between multiple trades. (If you’ve ever tried installing an industrial roll-up door, you know what we mean.)

As a side note, I can usually tell who’s worked in construction by how they react to the statement that “the door scope can be a headache.”

3. Clear Checks

Doors also come with well-defined checks: how do the door leaf dimensions in the schedule measure against the door frame detail? Is this hardware set matching the function of that door? Does this hardware set work with this door dimension? Will it maintain ADA clearance requirements? etc. etc.

I knew some of these rules working for General Contractors and owners with large door scopes, but we had to learn the rest by working directly with some door subcontractors.

4. Starting Narrow Builds Trust

This one is going to sound cheesy: choosing doors wasn’t about limiting ourselves, it was about earning trust. But frankly, it’s true.

By solving one critical problem really well, we could prove the value of our approach. And trust is what makes or breaks a project team.

What we learned from finding design mistakes related to doors:

- We found that Fieldworks being great at drafting RFIs and linking the supporting documents also helps architects and engineers close RFIs faster.

- Most design checks can be automated (I didn’t say it was easy though!). We still face some one-off situations from time to time where expert review is recommended.

- But most importantly, starting with doors gave us a tangible way to prove our vision. From here, we’re expanding into electrical, mechanical, and many more scopes. But doors will always be our proof point: a “simple” element that revealed the true complexity and opportunity inside construction drawings.